Spring srl is the leading Italian 3D printing service bureau, in the production of functional parts. In one of its latest projects, the company has created an airbox conveyor for a Moto2 team bike. The achieved results have been outstanding.

TARGETS

- Meet tight deadlines

- Produce a high-performance thermoplastic component

- Save production costs

IMPLEMENTATION PROCESS

STEP 1. Design

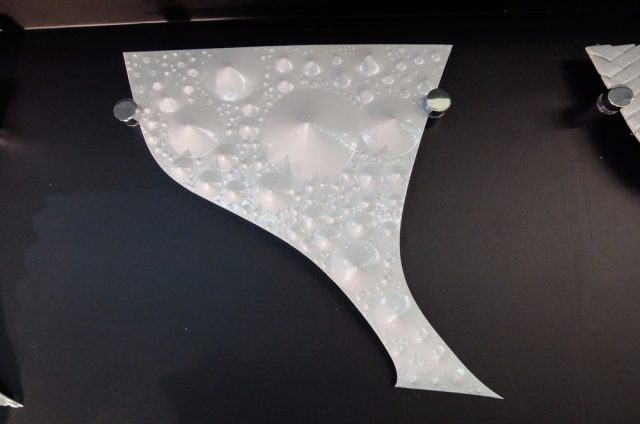

Spring srl has designed the airbox conveyor. The 3D model has been created with ribs to improve bike fluid dynamic.

STEP 2. Production

Racing bikes are exposed to extreme conditions such as high pressure, high temperatures and hydrocarbons. This is the reason why, in this project, Spring srl has used Nylon 12, one of the best performing materials of the FDM technology. This thermoplastic absorbs the strong vibrations and repetitive stress during the race. The client’s component, made up of 2 parts, has been printed, meeting extremely tight deadlines.

STEP 3. Finishing

Racing bikes are exposed to extreme conditions such as high pressure, high temperatures and hydrocarbons. This is the reason why, in this project, Spring srl has used Nylon 12, one of the best performing materials of the FDM technology. This thermoplastic absorbs the strong vibrations and repetitive stress during the race. The client’s component, made up of 2 parts, has been printed, meeting extremely tight deadlines.

STEP 4. Quality control

Spring srl offers the highest dimensional quality control, meeting the most demanding needs of the motorsport clients, guaranteeing the required tolerances.

ACHIEVED RESULTS

| PREVIOUS SOLUTION | SPRING SOLUTION | DIFFERENCE | |

| LEAD TIME | 8 working days | 2 working days | – 75% |

| COSTS | – | – | – 47% |

Send here your project, we will provide you with the best solution!