Spring srl, the Italian-based company with more than 20 years of experience in additive manufacturing of plastic materials, joins the aerospace Venetian cluster “Aerospace innovation and research“. With this new step, Spring srl becomes part of a high-performance team composed of companies and research institutes with different skills, able to meet the aerospace industry needs, completing major projects and R&D activities internationally.

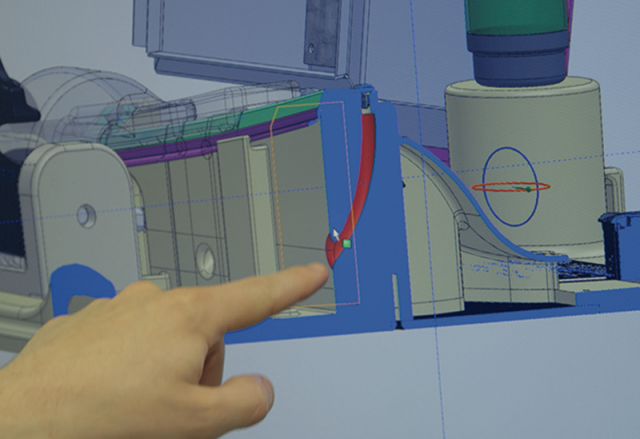

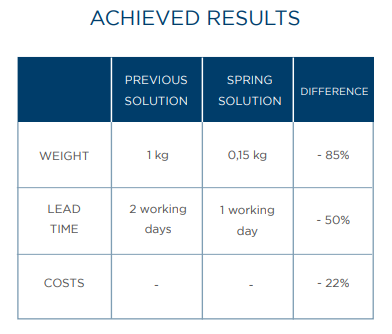

Spring srl provides aviation and military industry with light and resistant components with complex geometries, that contribute to reduce bigger projects time and costs. Spring’s know-how gained in working with these industries is also transferred to the space field, guaranteeing a high-quality level.

In the aerospace industry, a close collaboration among companies with different skills is needed to complete major projects. In Italy, also for this reason, these companies cooperate through regional aerospace clusters.

In the case of the Venetian region, the “Aerospace innovation and research” cluster, founded in 2019, gathers excellent research institutes with expertise on tests, validation, aircrafts qualification, satellites and high-tech companies able to build complex space systems. The “Aerospace innovation and research” cluster’s companies work on projects related to: space exploration, building of cutting-edge technologies for the resources exploitation on extraterrestrial sites, building modular habitats suitable for astronauts during long-term missions.

By joining the Venetian cluster, Spring srl is ready to make its contribution to international aerospace companies, providing its own quality, experience and the will to work on new additive manufacturing applications in partnership with the players of this articulated ecosystem.

SPRING srl: the additive manufacturing company certified for aerospace industry

Spring srl is an additive manufacturing company certified for components production for the aerospace industry (AS 9100:2016). The company, according to the industry standards, guarantees a full traceability on materials and process. Thanks to its own know-how, Spring srl is already partner of leading aeronautical and defence companies to which it guarantees a high-quality level in terms of performance and batches reproducibility.

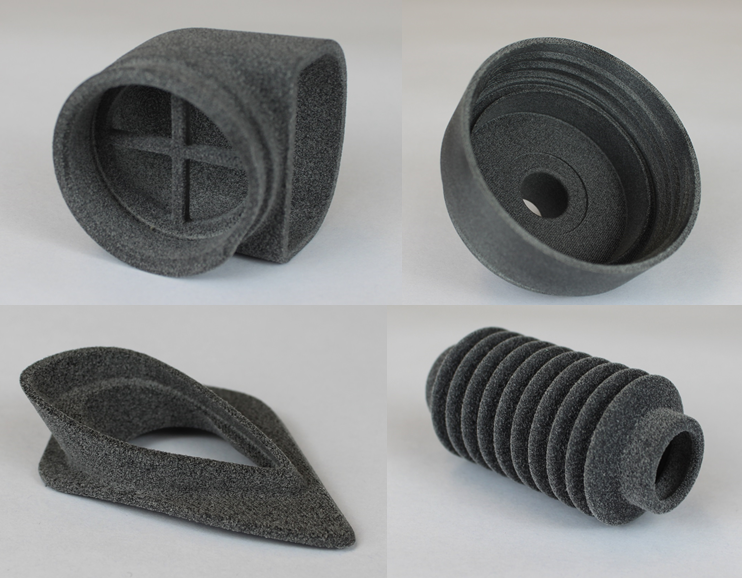

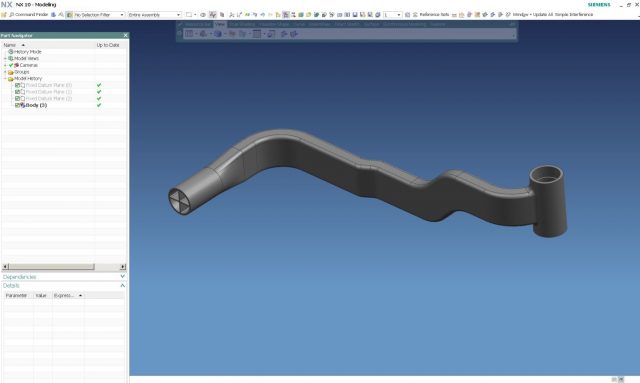

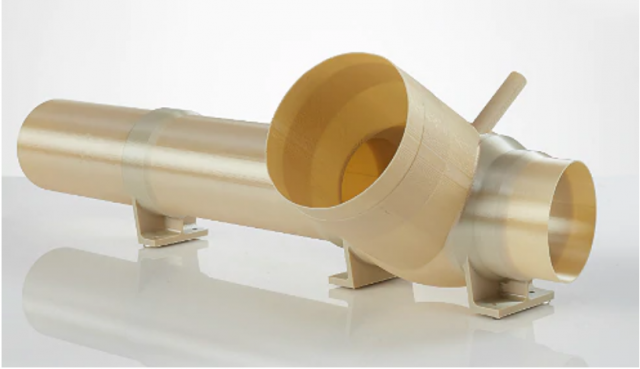

Spring srl provides the industry with air ducts, brackets, cable guides, electrical housings, connectors, jigs, production toolings, seat components, internal cabin components, window edges, door panels and more.

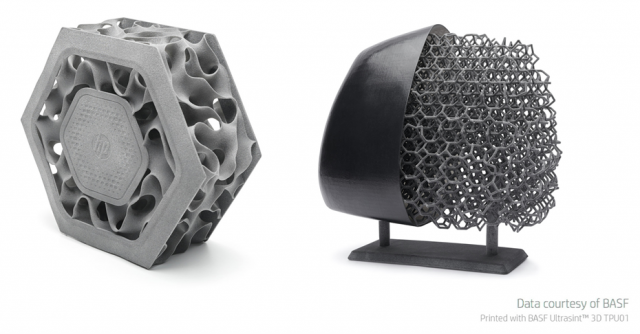

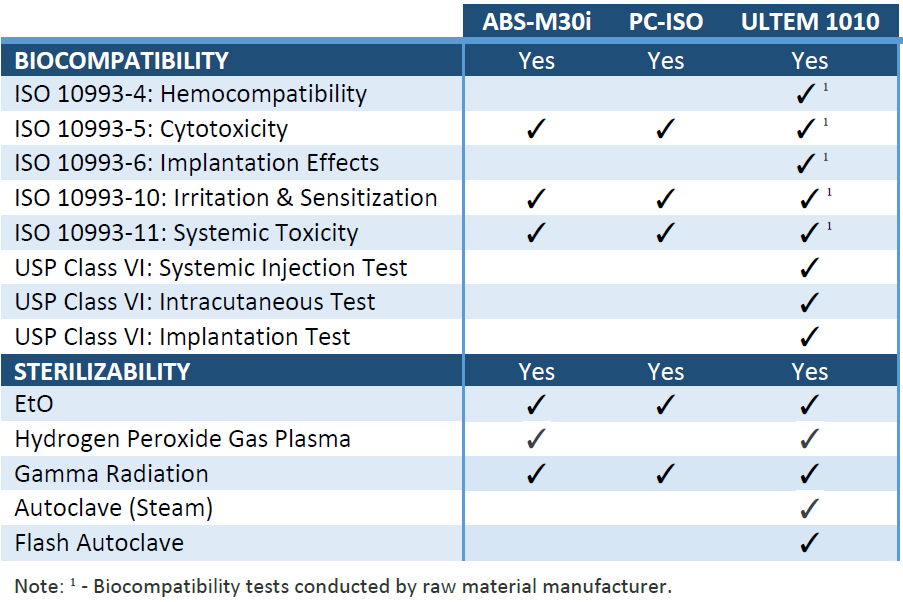

Some of the most interesting materials, chosen by Spring’s technical team for aerospace applications, are:

- ULTEM™ 9085 CG (PEI) is a fully self-extinguishing material, FST certified (Flame, Smoke, Toxicity), FAR 25.853 certified. ULTEM™ 9085 CG (Certification Grade) guarantees documented traceability from filament back to raw material lot number. Components built with this material offer an excellent chemical resistance and a great thermal, tensile and flexural strength.

- ANTERO 840CN03 (PEKK) combines the excellent physical and mechanical qualities of PEKK with electrostatic dissipative (ESD) properties. ANTERO 840CN03 is filled 3% by weight with carbon nanotubes. Components built with this material offer a great wear resistance, an excellent chemical resistance and an ultra-low outgassing.

Get in touch with us by this FORM and take benefits from additive manufacturing.

Photos:

– SpaceX e Nasa by Unsplash

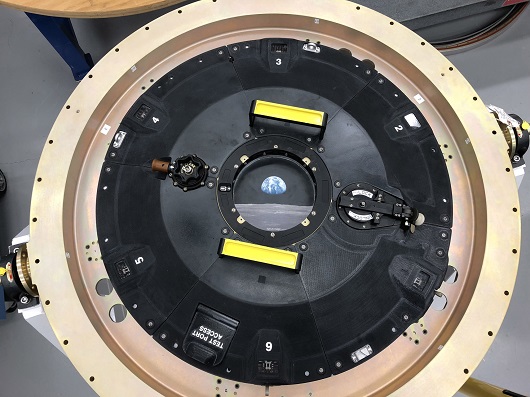

– Stratasys

Source: