Carbon Fiber - Spring

CARBON FIBER

Versatility, flexibility and speed of Additive Manufacturing and Rapid Prototyping technologies have been combined with internal R&D activities to offer new applications for parts printed in 3D with FDM technology, introducing the potential of composite fibers, in particular carbon fiber.

The applications available are:

- Soluble cores for lamination of complex geometries

- Carbon fiber prototypes

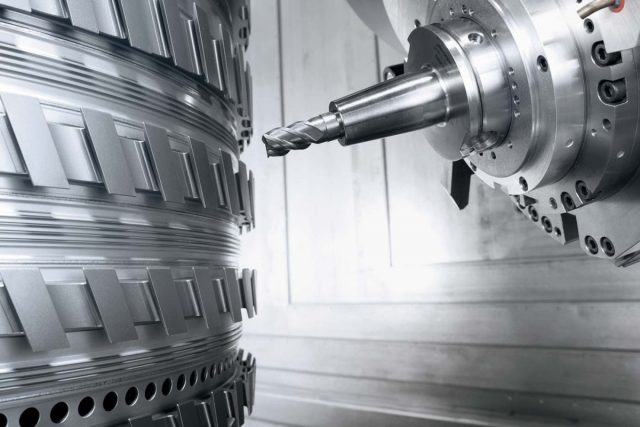

- Molds for carbon lamination

- Carbon layup

- Tools manufacturing (i.e. drilling and cutting fixtures)

- Quality check tools

Spring srl is now able to apply all the advantages gained from Rapid Prototyping systems in the creation and production of parts with complex geometries in carbon fiber or other composite material.

The main advantages are:

- speed

- precision

- high customization

- design freedom

- no production minimums

- production equipment elimination/reduction

These emphasize the possibility of reducing the production costs, shortening at the same time the times schedule too, without any geometric or structural changes to the part; it is also possible to realize complex monolithic pieces through the use of spindles soluble (or soluble cores).

ASSOCIATED WITH