There is something new in the air at Spring which has added the new AICS (Aircraft Interiors Certification Solution) certified Stratasys F900 printer to its fleet of machines. “Additive technology is evolving quickly, bringing in new professional systems is the best way of ensuring we satisfy demanding customer requirements.” – explains Roberto Toniello, co-owner of Spring Srl – “The AICS certification provides the traceability required for producing parts suitable for aircraft, enabling us to produce high performance components for the aviation and aerospace industries.”

The company currently possesses 5 Stratasys F900 systems, 2 of which are AICS certified, bringing the total number of professional 3D printers installed at its headquarters in Vicenza to 14.

“The quality of our systems and production processes enable us to take on and successfully meet the challenges set by the most crucial sectors” – adds Roberto Toniello – “We have combined experience with innovation to deliver an increasingly fast and professional service to our clients.”

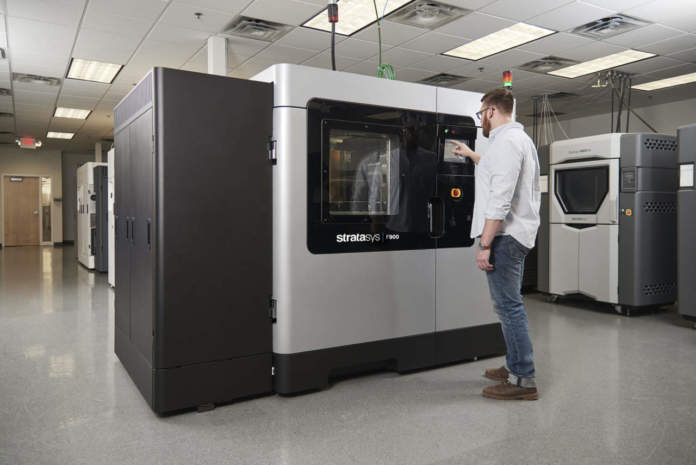

The Stratasys F900 professional printer is the largest in the Fortus range. With a build envelope of 900 x 600 x 900 mm, it enables us to produce large monolithic parts or groups of parts taking advantage of the greater available space and therefore reducing production times.

The system, which produces parts using the FDM (Fused Deposition Modelling) technology, uses a thermoplastic filament which is deposited, layer after layer, onto the build platform until the part is completed. This technology uses both standard thermoplastics (ASA, ABS, NYLON) to produce maquettes and visual details as well as high performance technical materials (ULTEM, CARBON FIBRE-FILLED NYLON, PEKK) for functional and direct use parts.

Grand dimensions for grand results with carbon fibre-filled nylon

Yet another great piece of news from Spring Srl: it’s using carbon fibre-filled nylon, with its excellent stiffness and lightness, with the Stratasys F900 systems. The significance of this is that it enables the company to produce large, extremely resistant and high performance monolithic parts for a variety of sectors such as aerospace, motorsport and automotive.

The combination of a high performance material such as carbon fibre-filled nylon containing 35% carbon fibre, the F900’s generous dimensions and the technological approach of Spring Srl, enables the company to meet requirements for producing functional parts within reduced production timescales and costs.

Benefits all the way with Spring Srl

It is a pioneer in the world of additive manufacturing, but the company doesn’t just print 3D components, it also works with its customers to re-engineer parts in order to guarantee maximum performance at the lowest possible cost.

Spring Srl has twenty years of experience in the Additive Manufacturing sector and continues to lead the European market in the production of high-end specialist components. Thanks to its quick turnaround times and quality of service, the company works with Italian and international clients in a variety of sectors to offer increasingly more innovative and high performance solutions.

Please send us your project to contatti@springitalia.com. It will be our prerogative to evaluate the technical feasibility and offer you the best possible solution!