MEDICAL AND HEALTHCARE FIELD – 3D PRINTING WITH FDM TECHNOLOGY

Spring srl increases its productive capabilities in the medical and healthcare field, making materials available that are resistant, biocompatible and ISO 10993 certified, such as:

-ABS-M30i Acrilonitrile Butadiene Stirene: This thermoplastic is ideal for the production of medical, surgical and pharmaceutical tools. Components manufactured with this material are sterilizable through gamma rays, ethylene oxide (EtO) or hydrogen peroxide gas plasma and can be used in direct skin-contact applications.

-PC-ISO Medical Polycarbonate: This thermoplastic is used for the production of tools for doctors, surgeons and dentists. Pieces manufactured with this material are sterilizable through gamma rays or ethylene oxide (EtO). PC-ISO offers excellent mechanical features, an outstanding traction strength and a temperature resistance up to 133 °C.

–ULTEM 1010 Polyetherimide: This thermoplastic is used for the production of medical applications and tools for food manufacturing (NSF 51). Parts produced with this material are sterilizable through gamma rays, ethylene oxide (EtO), hydrogen peroxide gas plasma or in autoclave. ULTEM 1010 is a self-extinguishing thermoplastic, that offers a notable mechanical resistance and high temperature strength, up to 216 °C.

Detailed information is available on the following link: https://www.spring-italia.com/product-category/fdm-en/?lang=en

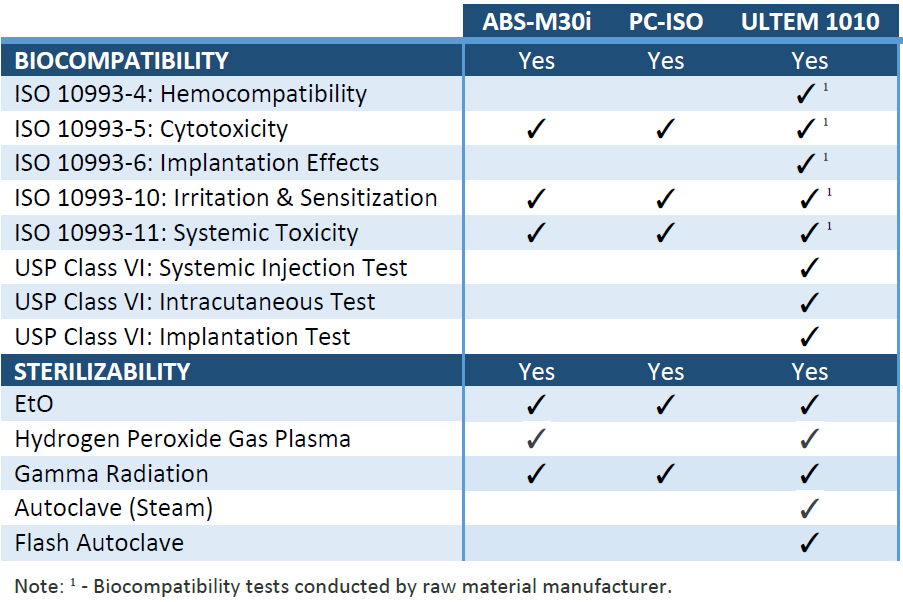

In the table below you can find the biocompatibility test results and the tested sterilization methods.

(Source: Stratasys)

Additive manufacturing for the medical field – Spring Srl

Additive production allows to obtain big benefits in terms of quality, execution speed, costs reduction and parts customization as long as professional systems, certified materials, processes that guarantee the produce traceability and know-how are employed.

At Spring Srl, with 20 years of experience, an excellent technical staff, 12 3D printing professional systems, a portfolio of more than 20 materials and an ISO 9001 certified production system, we provide appropriate solutions for the field.

The medical solutions that additive manufacturing can provide are rapid prototyping and end-use part production, medical and surgical tools.

These solutions are already available today at Spring Srl, and such allow to improve the healthcare and the creation of high-performance parts.

For any need or explanation, we invite you to contact us: https://www.spring-italia.com/contacts/?lang=en