Spring srl, an additive manufacturing company, achieved the certification AS 9100 on October 10, 2018 to meet urgent needs of the Aeronautic and Defense sector.

For aircraft manufacturers as well as systems, components and equipment, the principles of safety and reliability are considered essential values.

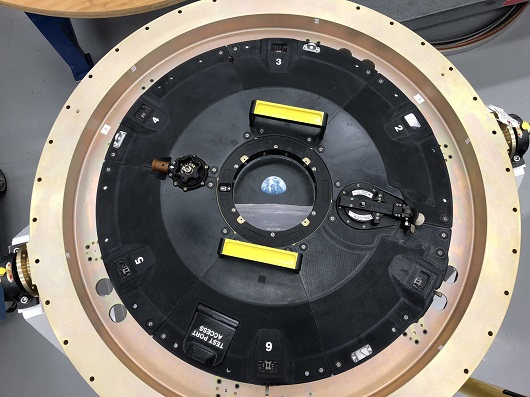

Spring srl is really proud to work with the Aeronautic and Defense industry providing functional components through the best professional systems of Additive Manufacturing. This is the result of 20 years of experience in professional 3D printing, thanks to the highest quality of the production process and applied technologies the company meets clients needs.

“Our corporate philosopy is based on the continuous improvement , this is also the reason why we invest a significant part of the budget in new technologies and innovation.” Says Roberto Toniello, Head of Quality Management at Spring srl.

“We continue innovating to meet challenging demands of an ultra high-performance sector such as the aeronautic. Each department cooperates to ensure required efficiency with the highest quality standards necessary to the sector.”

The company puts in place resources, equipments and expertises to guarantee its customers ultra high-performance products.

What is ISO 9100?

This is the management system certification for the quality of organizations and consists in an international standard that enables companies to increase customers satisfaction through the application of an efficient quality management system.

This certification stress the importance of business improvement and assessment of performances. In addition this certification requests specific methodologies to identify opportunities and risks in reaching expected results.

This new system ensures more attention on traceability and replicability of the process thanks to data sharing and reference metrics.

Another important focus is the ongoing training for a higher quality work of human resources. Moreover, the awareness of individual contribution to quality is reinforced.

To download the certificate click here.