Alignment and assembly jigs developed with additive technology

Additive manufacturing technologies, such as Fused Deposition Modeling or FDM, allow to produce ergonomic, optimized and custom-made jigs for the production floor. To understand benefits coming from this technology, let’s have a look at an example of an alignment jig and an assembly jig, related to the automotive field.

A custom-made alignment jig thanks to FDM technology

This jig, well-known as “Badge alignment tool”, is used by workers to accurately place a badge on a car. The Badge alignment tool is usually produced with CNC machines and metal, resulting too heavy and uncomfortable for workers.

The company decides to optimize the Badge alignment tool, by choosing FDM technology, ABS-M30 material and sparse fill style.

Sparse fill style is one of the most interesting chance offered by FDM technology. The sparse fill style, as opposed to the solid fill style, allows to develop resistant components composed of an internal grid, also with honeycomb structure. This condition enables to reduce the use of material and as a result, assures a further saving in terms of weight, time and costs, compared to an already favorable fill style such as the solid one.

The new custom-made Badge alignment tool has been optimized by the technical staff and produced by skilled workers. This new tool enables the company to get benefits such as:

- Increased productivity: The Badge alignment tool weight has been reduced by 72% compared to the previous solution. Moreover, the component design has been optimized in its ergonomics. Employees have been able to increase their productivity, thanks to these new conditions.

- Reduced time: FDM technology and sparse fill style have enabled a delivery time reduction by 92% compared to the previous solution.

- Reduced costs: FDM technology, sparse fill style and the new “design for manufacturing” have guaranteed a cost reduction by 58% for each Badge alignment tool.

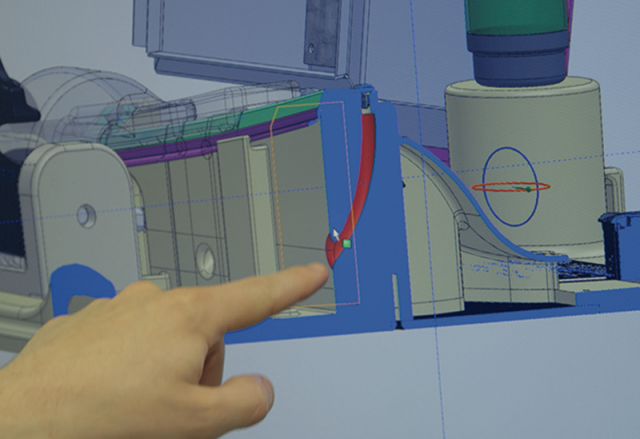

Custom-made assembly jig thanks to FDM technology

This jig is used by an automotive company’s workers, to assembly cars door seals. This jig is usually produced with CNC machines. The company needs to increase productivity related to this working step, that’s why technicians decide to develop a new assembly jig.

FDM technology, ASA material and solid fill style are chosen for this application.

This new optimized, custom-made assembly jig has been produced by skilled workers and shows now two main features:

- Improved ergonomics: FDM technology allows to overcome geometric limits, related to the use of more traditional methods. This chance has enabled the technical staff to re-design the assembly jig with a more focus on functionality. Indeed, it has been possible to insert internal hardwares in order to ease the working task.

- Reduced weight: Thanks to Asa material and the improved geometry, the new assembly jig weighs only 13 kg as opposed to the 58 kg of the previous solution.

The new assembly jig allows the company to get benefits such as:

- Saving time : The company saves hundreds of working hours, since each employee performs on average 250,000 cycles a year and the new jig enables a reduction of 4 second per assembly cycle. Indeed, thanks to the use of FDM technology, the company has shrunk the jig production from weeks to days.

- Saving costs: The ROI related to the jig cost is achieved within few months.

- Boosting safety: The new lighter and more ergonomic jig enables to reduce risks related to its use.

Spring srl – the additive manufacturing service for industrial applications

Spring srl is an additive manufacturing service, with over 20 years’ experience in the production of prototypes and functional components, with thermoplastic materials, for industrial applications. (ISO 9001:2015)

Spring srl’s highly-skilled technical staff chooses additive manufacturing technologies, materials and treatments in order to meet also the most demanding needs. With a portfolio of over 20 materials, a machinery composed of 3 different additive manufacturing technologies and 12 professional systems, Spring srl offers a wide range of solutions and a very fast delivery. The company produces not only prototypes and components, but also offers services such as engineering, design for manufacturing, 3D scanning for reverse engineering and a rich selection of finishes and treatments for post processing.

Source: https://www.stratasys.com/

Click here for more info on a control jig built with additive manufacturing.

Click here to send your request.