Prototypes are key for companies when it comes to design and realize new products. A company specialized in additive manufacturing optimizes production process, drastically reduces the Time to Market and provides the best mockups, samplings and short batches.

Spring srl owns a new Polyjet 3D printer that opens up new horizons for prototyping: so let us show you how this new machinery works, what its benefits are, its application fields and materials.

How does the Polyjet technology work?

Polyjet is a 3D printing technology with which it is possible to realize multi-color, multi-material prototypes and equipment. More than 360.000 colors are available with this machinery and it is also possible to print with realistic textures.

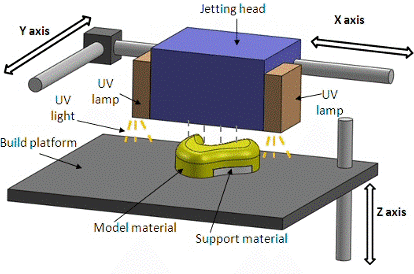

A 3D Polyjet technology uses a printing process similar to that in the 2D printer. However, a 3D Polyjet printer doesn’t work with ink drops but it deposits on a tray liquid-photopolymer layers and then it dries them with UV rays.

To realize a 3D model the printer deposits layers one by one. As the drying process is finished, models are ready to be used.

What are the main application fields of the Polyjet technology?

The Polyjet benefits are the highest print quality and accuracy, a wide range of materials and the possibility to print with realistic textures. This printer enables to realize smooth surfaces and very thin walls.

Below you can find the main application fields of the Polyjet technology:

- Highly realistic and multi-material prototypes. No more limits for designers that can work with very realistic prototypes, thanks to the possibility of mixing more materials in the same 3D model, realizing transparent components and combining more than 360.000 colors. Designers and developers can get prototypes and realistic models with multi-color elements, labels, realistic textures in a single operation, before sending them to mass production.

- Aesthetic components with precise and smooth surfaces. 0,032 mm layers enable to realize prototypes and aesthetic parts with very smooth surfaces. The level of detail is around 0.1-0.3 mm and it also depends on the geometry, on the size and the object orientation.

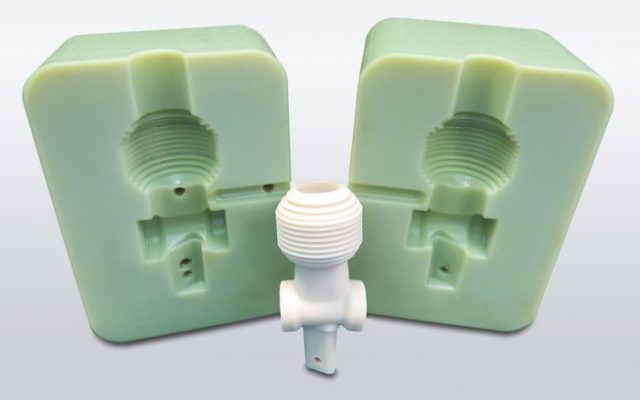

- Master molds for overmolding. With J750 it is possible to realize, in low-volume, technical- rubber matrices for overmolding. The polyjet process is faster and less expensive than more traditional methods that produce metal master molds.

- Components for medical industry and dental labs. Multi-color and flexible materials enable to realize realistic anatomical models. These models are used in doctor training and surgery prep, cutting costs of surgery room and improving patient care solutions.

What are the materials of the Polyjet technology?

- Vero family. The vero family materials are ideal for fit and form testing, for moving and assembled parts, concept and exhibition models. Unleash your creativity, we will provide you with the brighter colors.

- Simulated Polypropylene. These materials simulate the appearance and functionality of polypropylene. These materials are ideal for prototyping containers and packaging, flexible snap-fit applications and living hinges, toys, battery cases, laboratory equipment, loudspeakers and automotive components.

- Rubber-like. It offers various level of elastomer characteristics. It combines rigid materials for a variety of shore A values, from Shore A 27 to shore A 95. It is ideal for rubber surrounds and overmolding, soft-touch coatings and nonslip surfaces, knobs, grips, pulls, handles, gaskets, seals, hoses, footwear, and exhibition and communication models.

- Digital ABS. These materials simulate ABS plastics by combining strength with high temperature resistance. Ideal for functional prototypes, snap-fit parts for high or low temperature usage, electrical parts, castings, mobile telephone casings and engine parts and covers.

- High temperature : The only material with extraordinary thermal characteristics is RG525. Ideal for form, fit and thermal functional testing, high-definition models requiring excellent surface quality, exhibition models that endure strong lighting conditions, taps, pipes and household appliances, hot air and hot water testing.

To read:

Highly realistic prototypes make for better, faster design: Adidas Case Study