Case Study: Additive manufacturing industrial automation equipment

3D printing technology is increasingly approaching the industrial automation field .This Case Study explain how the automation-equipment realization process has been developed in order to significantly reduce costs and time of production.

TARGETS

- Realize equipment for the line processing and handling of the product

- Respect strict lead time

- Reduce costs

IMPLEMENTATION PROCESS

STEP 1: Reverse Engineering

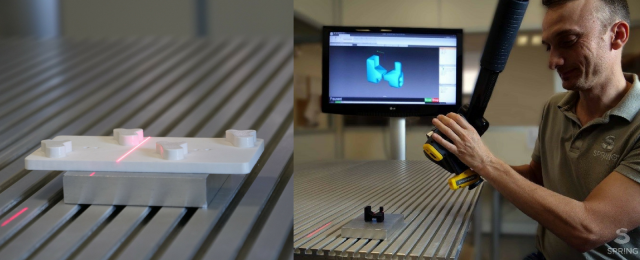

LThe activity starts with the acquisition of the product’s digital jig. The mathematic model of the element (customer’s product) is acquired through 3D Scanner, both the upper part, necessary to the realization of the collecting devices, and lower part necessary for the placements realization.

Scanner laser necessary for Reverse Engineering activity

STEP 2:Design

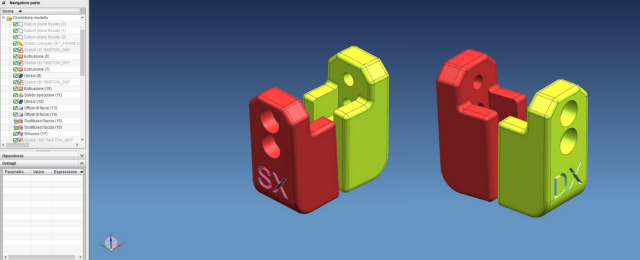

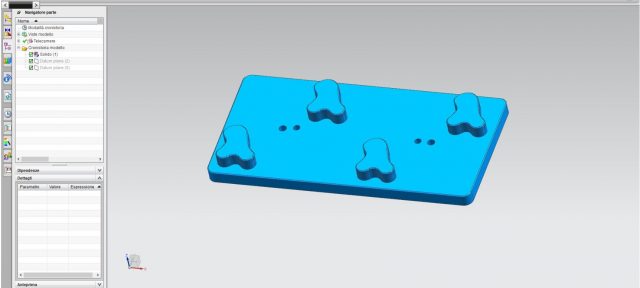

The technical department, thanks to the 3D measurements obtained through 3D Scanner, designed the collecting devices and the placements. The components development was realized with Cad 3D Systems installed in the company and thereafter optimized for Additive Manufacturing.

In this phase precise customer’s specifications were followed, such as details placement and extreme envelope of the placement with respective balance and fixing.

Collecting devices design (left and right)

Placement design

STEP 3:Production

After a technical analysis of the customer’s requirements we suggested the usage of two different materials:

• FDM technology (Fused Deposition Modeling) with Nylon 12 for the realization of the collecting devices

•FDM technology (Fused Deposition Modeling) with ASA for the realization of the placements

Spring has 10 FDM production system machines of the brand Stratasys that allow to realize monolithic parts of big dimensions or, like in this case, group parts and small pre-series.

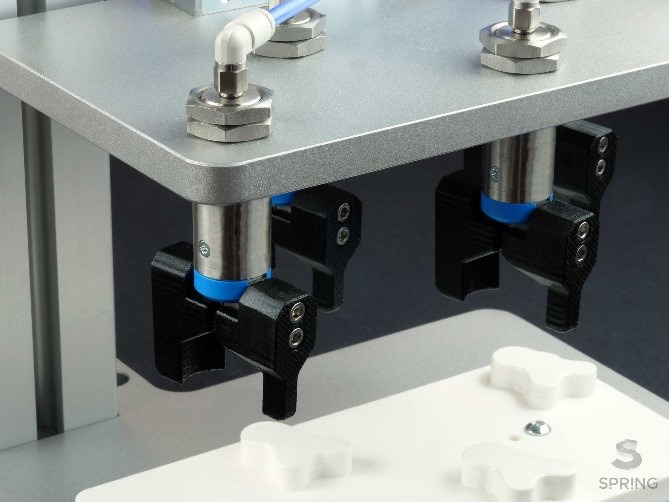

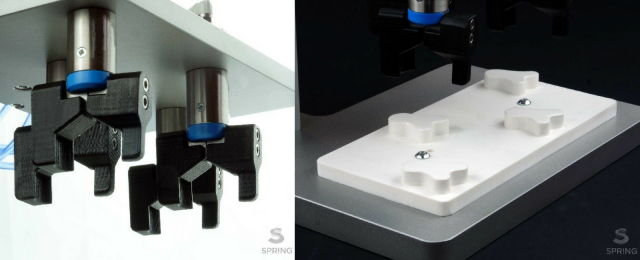

Collecting devices and placements realized with Additive Manufacturing

STEP 4:Quality control

Every realized part was tested with rigid quality controls in order to guarantee to the customer a complete service and a result that meets the initial urgent requests.

Collecting devices and placements quality control

In the following video you can see collecting devices and placements realized in Additive Manufacturing inserted in a working production line.

GAINED RESULTS

| Preavious solution | Spring Solution | Difference | |

| Lead time | 15 working days | 4 working days | -74% |

| Costs | – | – | -37% |

Please send us your project to contatti@springitalia.com. It will be our prerogative to evaluate the technical feasibility and offer you the best possible solution!