Case Study: Realization of a mold with additive manufacturing for a carbon support

In this Case Study you will understand how a mold for the realization of a quad’s rear mudguard was designed and produced.

OBIETTIVI

- To realize a mold with additive manufacturing reducing timing and costs compared to the production of the same item with traditional technology.

IMPLEMENTATION PROCESS

STEP 1: Design and production of the mold

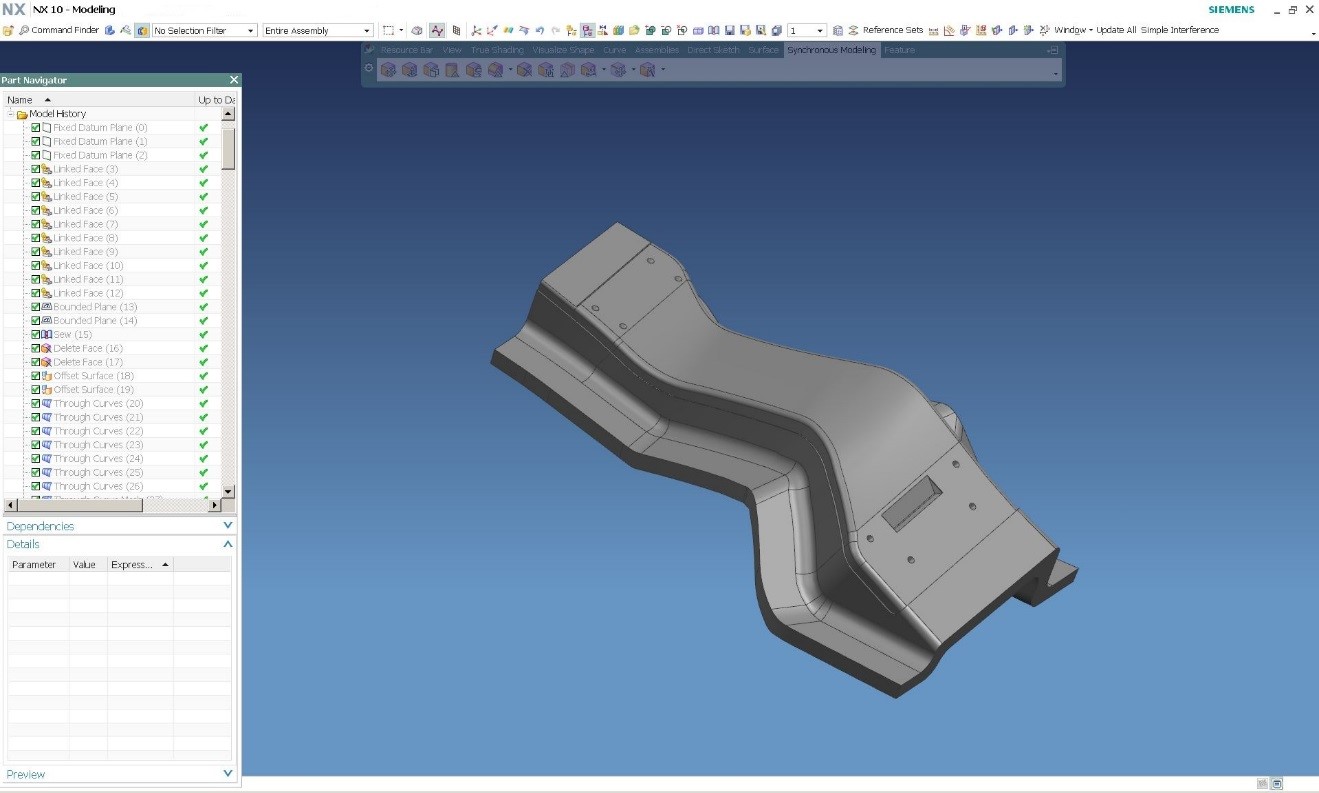

First of all the project of the mold was designed with CAD. During the design it was necessary to insert:

– trim lines to outline the perimeter of the mudguard support

– holes necessary to fix the detail to the vehicle

CAD mold design

After the file processing, the system Fortus 450 was prepared for the production of the mold with Nylon 12CF.

For the realization of the detail we chose Nylon 12CF (FDM technology). This thermoplastic carbon-charged composite has excellent technical characteristics such as high temperature resistance (143° C) and a resistance/weight ratio like no other on the market.

The selected material allows to laminate the carbon with standard autoclave cycles. The mold guarantee tens of cycles.

Carbon charge mold

STEP 2: Realization of the mudguard support with carbon

The mold realized with Additive Manufacturing was manually finished and treated with standard filler and releasing agents.

For the autoclaving process no particular setting was needed.

The solution offered by Spring allows carbon lamination with standard cycles.

STEP 3: Finishing

The carbon support was shaped following the trim lines and holes for fixing were set up.

Carbon support for autoclave post-working

Finished mudguard support fixed on the quad

ACHIEVED RESULTS

| PARTICULAR SOLUTION FROM CNC | SPRING SOLUTION | DIFFERENCE | |

| Weight | 2Kg | 0,50Kg | -25% |

| Lead Time | 2 working days | 1 working day | -50% |

| Build Time | – | 6h | N.A. |

| Costs | – | – | -43% |