Case Study: Realization of an air-conveyor

In this case study you will see how a nylon carbon-charged air-conveyor was realized. Traditionally, this detail would be produced with steal, requiring extra work and extra costs (molding in several parts). Use of 3D printing allowed the production of a monolithic piece that considerably reduced production times and improved the fluid dynamic of the detail.

TARGETS

- Realization of a monolithic detail, completely seamless

- Considerably reduction of pressure drops when operating

- Respect strict delivery times

The use of FDM technology and carbon-charged Nylon allowed to:

- Realize a hollow detail with high geometrical complexity

- Realize a detail with high mechanical performances

- Reduce the detail weight

IMPLEMENTATION PROCESS

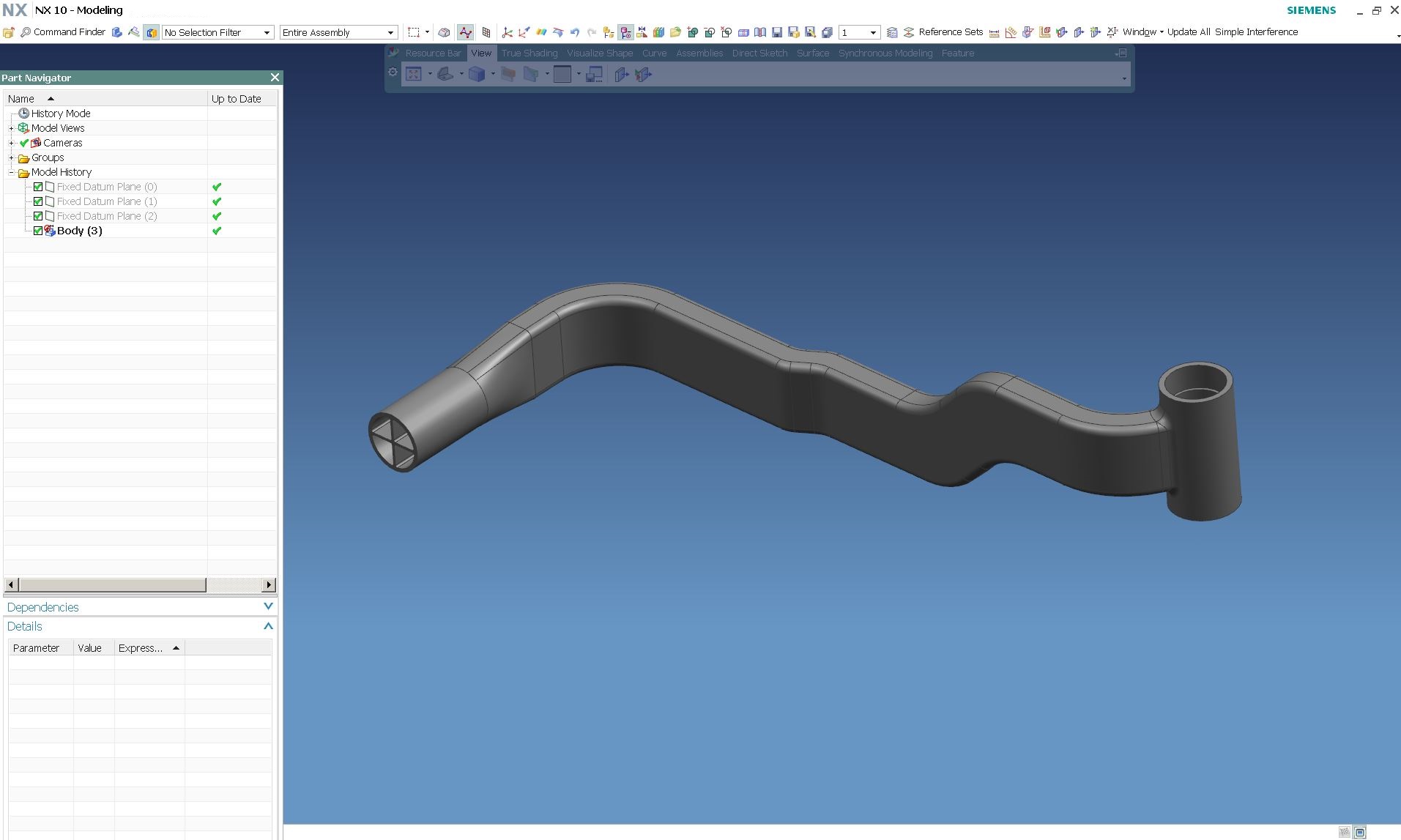

STEP 1: Design

The activity has been developed starting from the design of the required detail: the 3D model was improved and optimized according to the customer’s needs.

CAD air-conveyor design

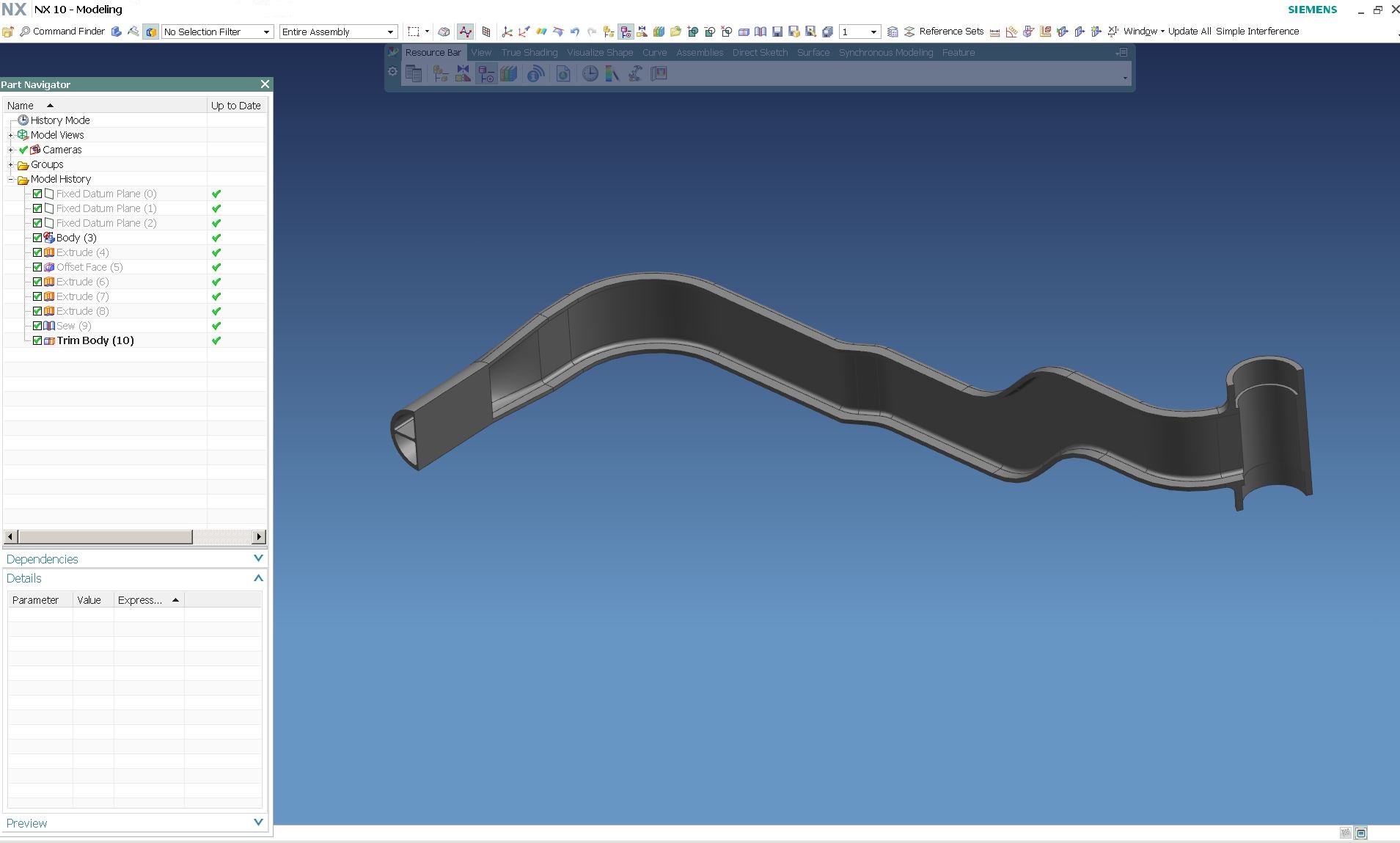

Structural ribs were inserted in each edges with the target of realize parts able to resist to the hose fixing.

Sectioned conveyor

STEP 2: Production

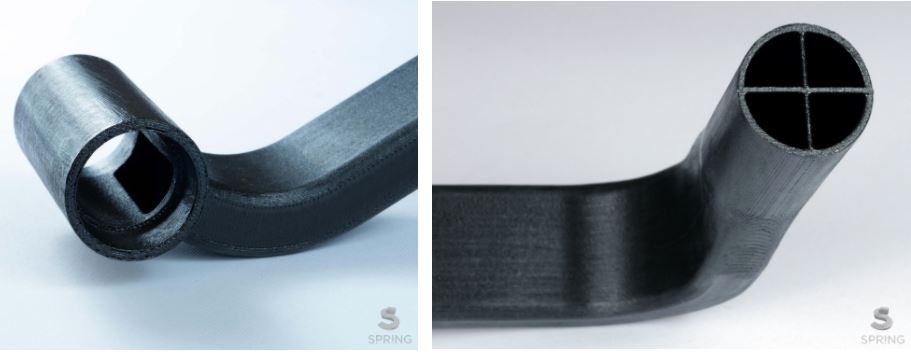

Spring’s 3D printers allowed the realization of a monolithic piece, without any need of seams. The material chosen for the realization of the conveyor is Carbon Charged Nylon (FDM technology), extremely rigid, resistant and ideal for Metal Replacement applications.

The possibility of using a soluble support allowed to optimize the detail geometry without any design restraint.

Particular of the hose onset

STEP 3: QUALITY CONTROL

During the last phase we could verify the coupling diameter with our laser scanner quality control system.

ACHIEVED RESULTS

| Preavious solution | Spring solution | Difference | |

| Weight | 1 kg | 0,15 kg | -85% |

| Lead time | 2 working days | 1 working day | -50% |

| Costs | – | – | -22% |

Please send us your project to contatti@springitalia.com. It will be our prerogative to evaluate the technical feasibility and offer you the best possible solution!